Spray paint, spray plastic, water transfer, and thermal transfer are common surface treatment technologies in modern industry, each of which has its own unique characteristics and scope of application. The following is a detailed analysis of these technologies.

Spray paint

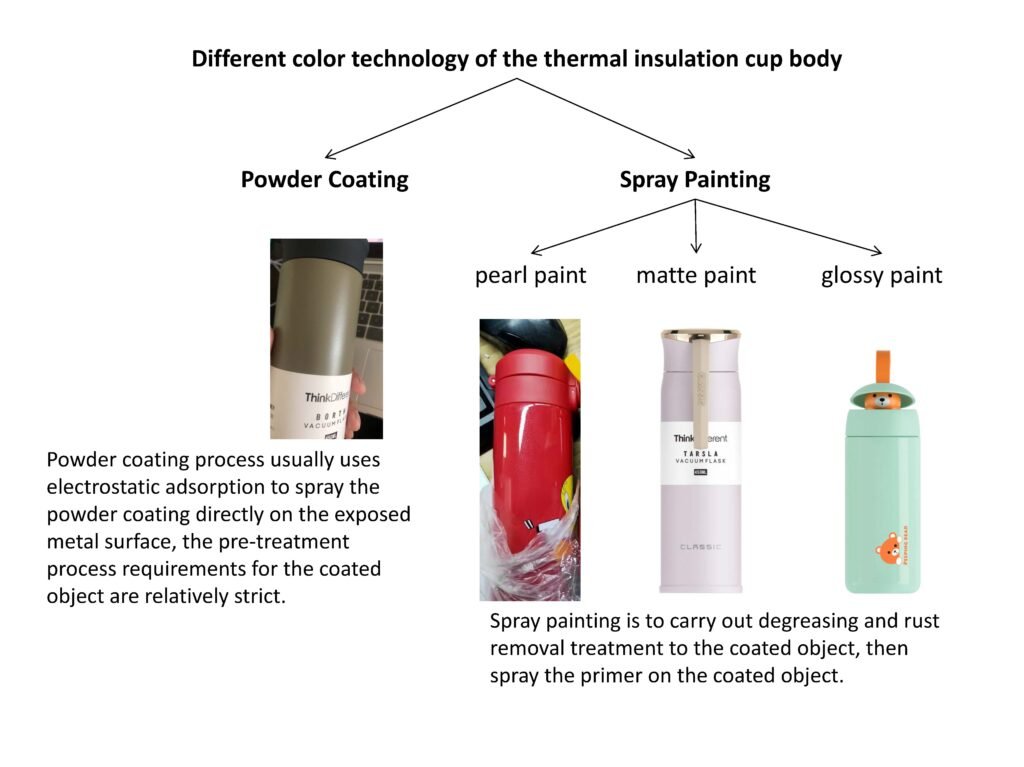

Spray painting is a traditional surface coating technology, mainly through the spray gun to evenly spray the paint on the surface of the object. This technology is flexible and can form a uniform coating on the surface of objects of various shapes and materials. Spray paint coating has good decorative and protective properties, which can prevent the object from corrosion and wear.

Main steps:

1. It is necessary to comprehensively clean the body of the thermos cup to remove the grease, dust, and other impurities on the surface. This step is very important because any residual contaminants will affect the quality and adhesion of the film;

2. Polish the insulation cup body to make its surface reach a certain roughness to enhance the adhesion of the paint film;

3, through pickling, phosphating, and passivation steps. Pickling is to remove the oxides and rust on the thermos cup, and phosphating is to form a phosphate film on the thermos cup to prevent rust and improve the adhesion of the paint film. Passivation is to protect the surface of the thermos body to prevent chemical reactions during the subsequent coating process. This step is to improve the coating performance of the thermos cup body;

4, after the pretreatment is completed, a layer of primer will be sprayed, which helps to improve the adhesion of the paint film and also to fill the small defects on the surface of the thermal cup. After the primer is sprayed, it needs to be dried.

Spray molding

Spray, also known as powder spraying, is a technology that uses powdered paint to paint. Compared with spray paint, spray plastic does not use organic solvents, so it is more environmentally friendly. The powder coating is uniformly adsorbed on the surface of the object under the action of static electricity and then cured into a hard coating by high-temperature baking. The spray coating has excellent corrosion resistance, wear resistance, and adhesion. Suitable for the surface treatment of metal products, especially products used in outdoor environments.

Main steps:

1, in order to ensure that the spray layer can be evenly and firmly attached to the cup, it is necessary to clean, polish, and remove oil and other steps on the surface of the cup body to remove dust, oil, and other impurities on the surface.

2, spray gun equipment, through the compressed air to atomize the paint and evenly spray on the surface of the cup body.

3, put the cup body into a high-temperature oven to promote the rapid drying of the paint, and the cup body coated with paint is cured to form a hard protective layer.

Water transfer printing

Water transfer is a technique that uses water as a medium to transfer a pattern from the transfer paper to the surface of an object. The technique can achieve full coverage of complex patterns and is suitable for irregularly shaped objects. In the process of water transfer, the pattern on the transfer paper is first dissolved by water and then transferred to the surface of the object under pressure. Finally, the pattern is fixed by heating or natural drying. Water transfer technology is widely used in plastic, metal, wood, and other materials for product surface decoration.

Main steps:

1, make a water transfer film. The film is usually made of special plastic, which is printed with the pattern to be transferred;

2. Thoroughly clean and dry the thermos body to ensure that there are no stains or moisture on its surface;

3. Paste the made water transfer film on the thermos cup that has been coated with water transfer agent;

4. Immerse the thermos cup with the water transfer film in water. With the flow of water, the pattern on the water transfer film will be transferred to the thermos cup;

5, the water transfer treatment of the thermos cup for drying and curing.

Heat transfer printing

Thermal transfer is another pattern transfer technology, which is different from water transfer in that it mainly transfers the pattern from the transfer film to the surface of the object by hot pressing. The pattern on the thermal transfer film is melted under high temperature and pressure, and then tightly adhered to the surface of the object. This technique is suitable for pattern transfer on smooth hard surfaces, such as plastics, metals, ceramics, etc. Thermal transfer coating has good wear resistance and weather resistance, suitable for outdoor use of products.

Main steps:

1. Print the designed pattern on a special heat transfer paper. This kind of paper is usually thicker than normal paper because it needs to withstand higher temperatures;

2. Paste the heat transfer paper on the surface of the thermos cup;

3. Put the thermos cup pasted with heat transfer paper into the heat transfer machine. With the heating of the machine, the pattern on the heat transfer paper will be transferred to the thermos cup;

4. Cool and cure the thermos cup after heat transfer processing.

Each surface treatment technology has its specific application scenarios and advantages. When choosing the right technology, it is necessary to consider factors such as the material, use environment, cost, and environmental protection requirements of the product. With the advancement of science and technology, these technologies are also constantly developing and improving, and more efficient and environmentally friendly surface treatment methods may appear in the future.