Stainless steel, as a widely used alloy material, is loved and recognized for its excellent corrosion resistance, beautiful appearance, and good mechanical properties. In our daily lives, we often come into contact with a variety of stainless steel products, such as kitchenware, furniture fittings, decorative objects, etc., which not only bring convenience to our lives but also add a sense of modernity and aesthetic value.

Although the name of stainless steel with “stainless” word, it does not completely will not rust, but compared to other types of steel, more difficult to rust and corrosion. The corrosion resistance of this material is mainly due to the formation of a very thin but strong layer of oxidized film on its surface, which protects the interior of the material from the external environment.

The classification of stainless steel, there are commonly divided according to its constituent elements and microstructure of several categories, including austenitic stainless steel, ferritic stainless steel, martensitic stainless steel duplex stainless steel, and so on. Austenitic stainless steel, such as our common type 304 and 316, is popular for its good overall performance and non-magnetic; ferritic stainless steel is favored for its better heat resistance and cost-effectiveness; martensitic stainless steel is known for its high strength and hardness; duplex stainless steel combines the advantages of austenitic and ferritic structures, with better strength and corrosion resistance.

However, the quality of stainless steel products on the market varies, and how to accurately identify the type and quality of stainless steel, has become a common concern of consumers and industry insiders. The correct identification method can not only help us buy a reliable quality of stainless steel products but also to a certain extent avoid the waste of resources and economic losses. Therefore, understanding and mastering stainless steel differentiation skills is of great significance to ensure the performance and safety of the material. Next, we will explore several effective stainless steel differentiation methods to help you better understand and choose stainless steel products.

Compositional differences

201 stainless steel typically contains about 17% chromium and about 4.5% nickel, as well as some amount of manganese. It is an economical stainless steel with a high manganese content but a lower nickel content.

304 stainless steel is mainly composed of more than 18% chromium and more than 8% nickel, sometimes with molybdenum added. It has good corrosion resistance and processability and is one of the most common types of stainless steel.

316 stainless steel adds about 2% of molybdenum based on 304, which makes it have better resistance to pitting and chloride corrosion, especially suitable for use in seawater and other environments containing chlorides.

Identification of color

After pickling stainless steel surface was colored silver white and clean. Chromium-nickel stainless steel color silver white jade color; chromium stainless steel color white slightly gray luster is weak; chromium-manganese-nitrogen stainless steel color and chromium-nickel stainless steel is similar to slightly lighter. Without pickling stainless steel surface color, chromium-nickel steel is brownish white, chromium steel is brownish black, and chromium manganese nitrogen is black.

Magnetic identification

201 stainless steel has strong magnetism and can be attracted by magnets.

304 stainless steel is usually non-magnetic in the annealed state but may exhibit some magnetism after cold working.

316 stainless steel has a similar magnetic profile to 304 but may exhibit magnetism under certain specific conditions.

Corrosion resistance

201 stainless steel has relatively poor corrosion resistance, especially in highly corrosive environments, more likely to rust.

304 stainless steel has good corrosion resistance and is suitable for most environments, but may corrode in highly chlorinated environments.

316 stainless steel has more excellent corrosion resistance due to the presence of molybdenum, especially in seawater and high chloride environments.

Heat resistance

304 stainless steel is more heat resistant than 316 due to its higher chromium content and ease of welding, allowing it to be used in extreme temperature environments.

Although 316 stainless steel also has good heat resistance, its main characteristic is resistance to chloride corrosion, so it may not be as good as 304 stainless steel in high-temperature environments.

Spark Test

Lightly polish both types of stainless steel with a grinder or emery wheel and observe the length and thickness of the sparks. 201 stainless steel sparks are usually longer, coarser, and more frequent, while 304 stainless steel sparks are shorter, finer, and less frequent.

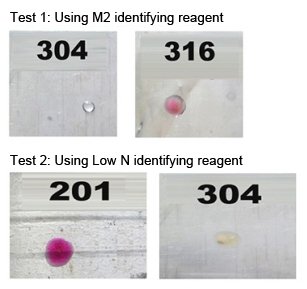

Chemical Reagent Test

Specific chemicals can be used to test the nickel content of stainless steel to differentiate between 201 and 304 stainless steel. For example, using a copper sulfate test, 304 stainless steel will not react with copper sulfate, while 201 may. Certain testing solutions may turn red on 201 and light green or other colors on 304. Different test solutions, drop to 201 material and 304 material will show a different color, which can be based on the color of the test solution to remind us to distinguish stainless steel material.

Spectral or chemical analysis

The composition and type of stainless steel can be accurately identified using spectral or chemical analysis, which is a scientific and accurate method but requires specialized equipment and knowledge.

Stainless steel 304 insulation cup and stainless steel 316 insulation cups each has their unique advantages and disadvantages, Choosing the right insulation cup material needs to be based on individual needs and the use of the environment.

Stainless steel 304 insulation cup

Advantages.

Lower cost: due to the relatively low cost of 304 stainless steel material, the price of 304 insulation cups is also more friendly, and more easily accepted by the majority of consumers.

Lightweight and easy to carry: 304 material insulation cup is usually thinner, so it is lighter in weight and easier to carry.

Widely used: 304 stainless steel is widely used in many fields such as home, kitchenware, and automobile due to its good corrosion resistance and processability.

Disadvantages:

Slightly inferior thermal insulation effect: compared with 316 stainless steel insulation cup, 304 insulation cup has a slightly worse thermal insulation effect, and the insulation time is relatively short.

Relatively short service life: due to the relatively simple production process and the relatively more general materials used, the service life of 304 insulation cups may be shorter than that of 316 stainless steel insulation cups.

Stainless Steel 316 Insulated Mug

Advantages.

High corrosion resistance: 316 stainless steel is low-carbon stainless steel with higher corrosion resistance and high-temperature resistance, especially in a more corrosive environment with, longer service life.

High strength: 316 stainless steel insulation cup is stronger than 304 stainless steel insulation cup, more durable, and not easy to deform.

Good heat resistance: 316 stainless steel insulation cup can withstand higher temperatures, is not easy to deform, suitable for high-temperature environments.

Disadvantages:

Higher price: due to the higher cost of 316 stainless steel material, the price of 316 insulated cups is relatively high, which may not be suitable for consumers with limited budgets.

Higher weight: Compared with 304 material, 316 stainless steel insulation cups are made of thicker material and therefore weigh more, which may be a little inconvenient to carry.

When choosing a stainless steel insulated cup, you can weigh the above advantages and disadvantages. If the budget is limited and the insulation effect and lightweight have high requirements, you can choose a 304 stainless steel insulation cup. If you need to use it in a more corrosive environment, or the durability and high-temperature resistance of the insulation cup have high requirements, 316 stainless steel insulation cup is a better choice. Regardless of which material, you should ensure that you choose products produced by regular manufacturers to ensure quality and safety in use.